The possibilities for additive manufacturing seemed to just be nearly endless. Rapid application development was the first application of additive manufacturing processes for testing and development models. The features of printing technology over traditional production are driving its rising popularity. These advantages, however, are frequently accompanied by flaws. The flaws provide the potential for improvement through the creation of novel additive manufacturing singapore biodegradable polymers. This Committee’s activity focuses on acquiring knowledge, stimulating research, and putting technology into practice through the development of guidelines. Every end-user typically finds the best incremental production model for customer needs, followed by the preferred materials again for methodology and purpose.

Production

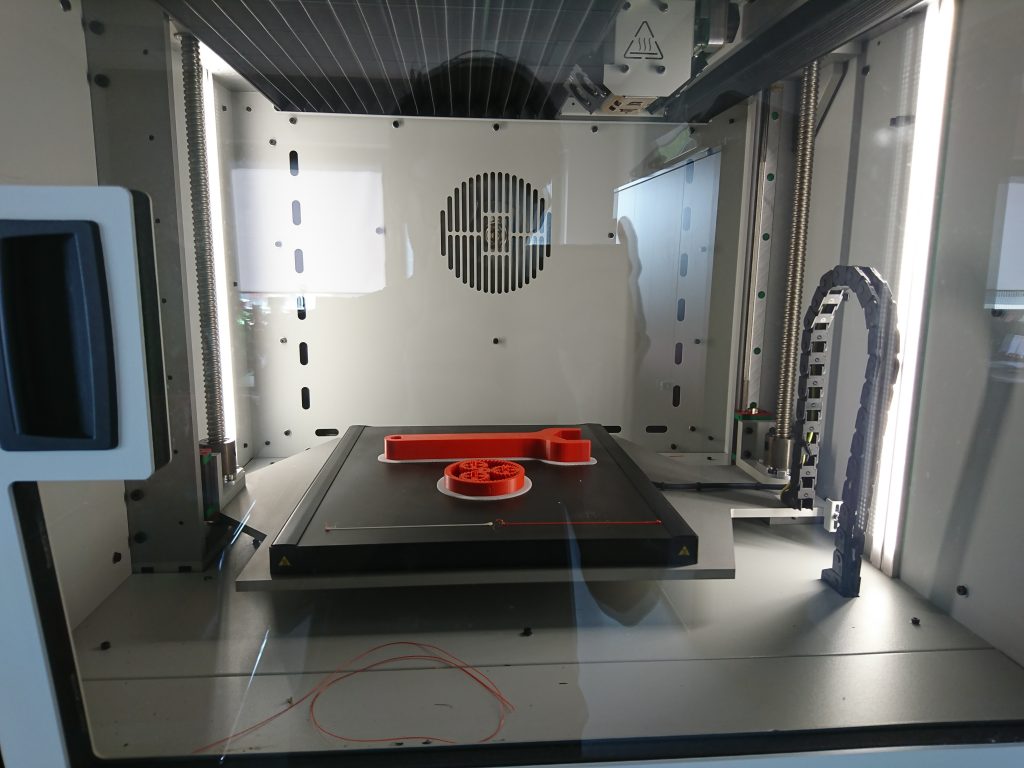

3d printers, often known as diagnostic, describe a variety of cutting-edge technologies for creating three-dimensional objects.

These items are made using additive manufacturing singapore digital modell=ing or even other online data inputs and could be practically any size or configuration. This topic has gotten a lot of interest recently since that opens up new possibilities for polymeric in forthcoming manufacturing.

Operation

Photopolymerization, package elements, powder particles melting, and vapor deposition have been the most common design and manufacturing procedures for materials. Some materials employed within those processes might be liquids, powders, or solids. Several chemical kinds and shapes of polymeric composites utilized within every operation are explained in further depth below. The specifications of respective parental screen printing methods describe printed books consisting of chemicals and polymeric materials. Polyesters, including both semisolid shapes, have typically been chosen as the stacking element due to various their availability shapes, dimensional stability, and finished qualities.